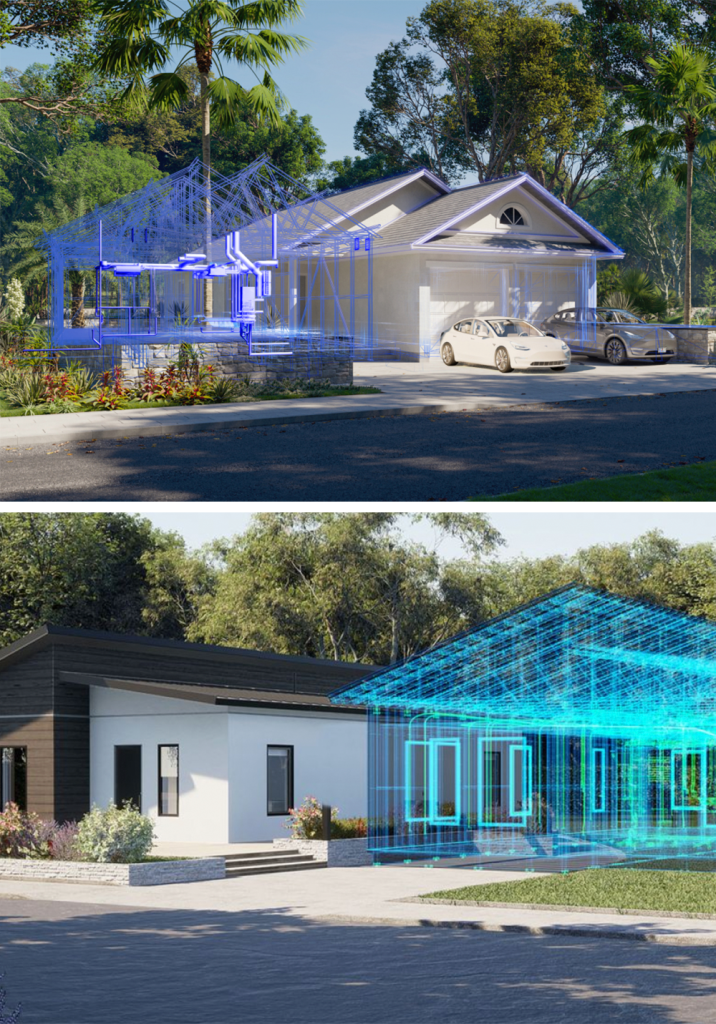

“MxD exemplifies how innovation networks accelerate digital transformation – taking manufacturers from concept to roadmap through demonstrations and focused workshops. Their Chicago facility showcases how Siemens’ ability to combine the real and digital worlds helps them to chart a course to increased resilience, productivity and adaptability.”