February 29, 2024

Cross Institute Collaboration Project

The Collaboration Project Team will develop a secure communication framework enabling virtual verification and validation of parts across additive manufacturing (AM) types and platforms. This includes universal data, types of sensors available per machine, sampling rate, and interdependence data.

Proposed Solution

Impact

Outcome

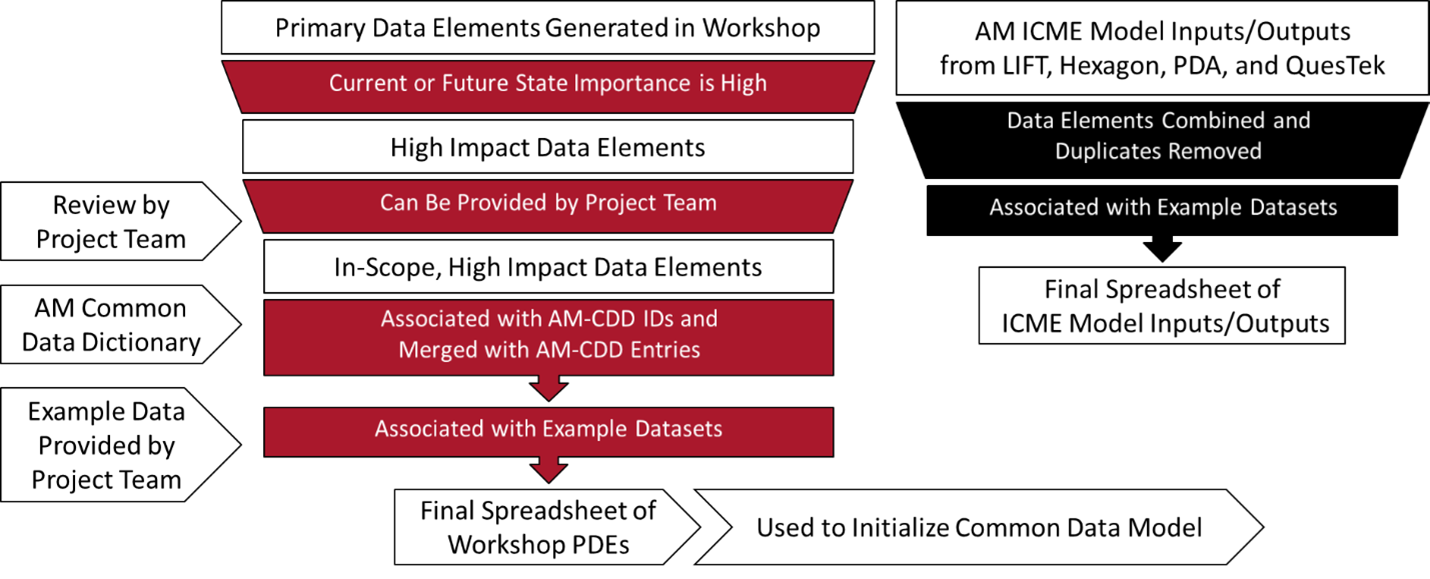

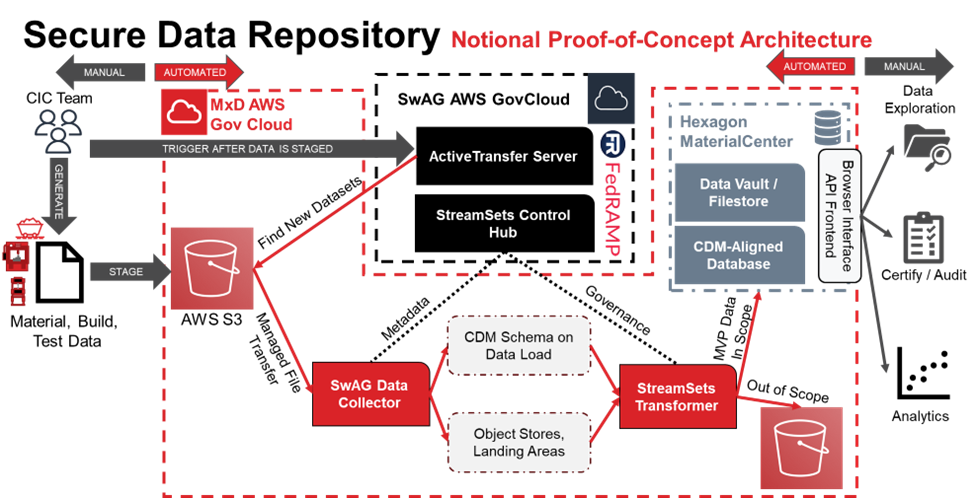

The MxD-led team focused on the creation of the Secure Data Repository, creating a proof-of-concept architecture for unifying AM data from specification, production, and testing into a unified digital thread build log. Doing so required the development of a functionalized common data model for additive manufacturing built on the pre-existing AM-CDD and AM-CDM as baseline. The revised/enhanced data model is documented in a formal modeling language and will be shared with the NIST working group which originally created these assets. These outcomes are documented with a reference architecture, system integration plan/requirements, user guide/manual, and demonstration.

Additionally, MxD and LIFT have collaborated to develop an analysis report and roadmap for the inclusion of model-based methods in the qualification of AM parts. LIFT focused on the physics-driven and integrated computational materials engineering (ICME) portion of this roadmap while MxD authored the Roadmap for Use of AI/ML and Deep Learning in Qualification and Certification of AM Parts. This document is being refined into a publication version for full release.

Read more about this Project